Fabric Coating vs TPU Bonded

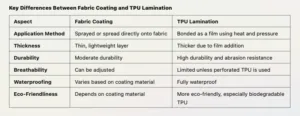

In the textile industry, surface treatments and finishing techniques significantly enhance fabric functionality, adaptability, and market value. Among these, fabric coating and TPU (Thermoplastic Polyurethane) bonding are two popular methods widely employed to meet diverse demands across industries. While both processes provide added functionality like water resistance, durability, and breathability, they differ significantly in their methodology, performance, and applications. This article delves into the key distinctions between fabric coating and TPU bonding, highlighting their respective advantages and suitable applications.

Understanding Fabric Coating:Coating vs TPU Bonded

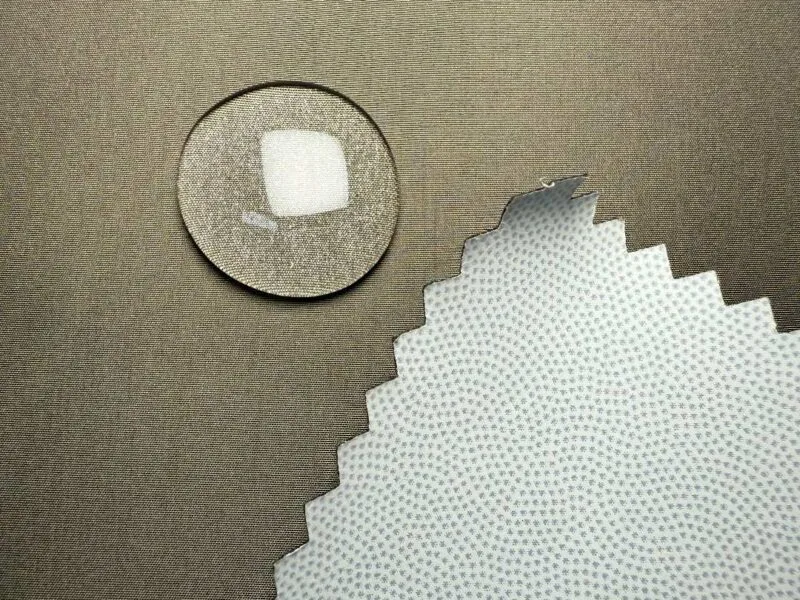

Fabric coating involves applying a layer of polymer or chemical substance directly onto the fabric’s surface. Common coating materials include polyurethane (PU), polyvinyl chloride (PVC), and silicone. This technique enhances the fabric’s properties by creating a protective or functional barrier.

Key Features of Fabric Coating:Coating vs TPU Bonded

1.Direct Application: The coating material is spread or sprayed onto the fabric, forming a thin, even layer.

2.Customizable Properties: By altering the coating formula, manufacturers can achieve varied effects, such as water resistance, fire retardancy, or UV protection.

3.Economic Production: Coating generally has a lower production cost compared to bonding processes.

Advantages of Fabric Coating:Coating vs TPU Bonded

•Lightweight Design: The thin application adds minimal weight to the fabric, making it suitable for applications requiring mobility, like rainwear or sportswear.

•Versatility: Coated fabrics can be used in a wide range of industries, from fashion to industrial equipment.

•Breathability Options: Certain coatings maintain the fabric’s breathability while offering added protection.

Applications of Coated Fabrics:Coating vs TPU Bonded

•Outdoor gear such as tents, umbrellas, and jackets.

•Industrial materials like tarpaulins and conveyor belts.

•Upholstery and automotive interiors for improved durability and appearance.

Understanding TPU Bonding:Coating vs TPU Bonded

TPU bonding, on the other hand, involves bonding a TPU film to the fabric using heat and pressure. TPU is a flexible and resilient polymer known for its elasticity, toughness, and water resistance. The bonding process creates a unified structure where the film and fabric act as a single entity.

Key Features of TPU Bonding:Coating vs TPU Bonded

1.Bonding Process: TPU is fused with the fabric rather than coated on its surface, creating a permanent attachment.

2.Enhanced Durability: Bonded fabrics exhibit superior abrasion resistance and longevity compared to coated fabrics.

3.Eco-Friendliness: TPU films are often more environmentally friendly than PVC or PU coatings, as they are biodegradable and free from harmful chemicals.

Advantages of TPU Bonding:Coating vs TPU Bonded

•Superior Waterproofing: TPU bonding ensures complete water impermeability, ideal for high-performance applications.

•Elasticity and Flexibility: Bonded fabrics retain their stretch and conformability, suitable for applications requiring movement.

•High Durability: The bonding process significantly enhances the fabric’s resistance to wear, tear, and environmental stress.

•Eco-Conscious Choice: TPU is a greener alternative to many coating materials, aligning with sustainable practices.

Applications of TPU-Bonded Fabrics:Coating vs TPU Bonded

•Protective clothing, such as hazmat suits and medical gowns.

•Outdoor and performance gear, including backpacks, raincoats, and ski wear.

•Technical textiles used in sports, healthcare, and industrial sectors.

Choosing the Right Method:Coating vs TPU Bonded

The choice between fabric coating and TPU bonding depends on the intended application, budget, and desired performance characteristics. Here are some considerations to help in decision-making:

1.Budget Constraints: Coating is generally more economical and suits low- to mid-range performance requirements.

2.Performance Needs: For extreme waterproofing, elasticity, and longevity, TPU bonding is the superior choice.

3.Sustainability Goals: TPU bonding, with its eco-friendly properties, is preferred for brands prioritizing environmental consciousness.

4.Breathability vs. Protection: Coating offers adjustable breathability, while TPU bonding provides better protection at the cost of reduced air permeability.

Future Trends in Fabric Coating and TPU Bonding:Coating vs TPU Bonded

With advancements in technology, both coating and bonding processes are evolving to offer better performance and sustainability. Developments include:

•Smart Coatings: Incorporating nanotechnology and responsive materials for added functionality, such as self-cleaning or temperature regulation.

•Recycled TPU Films: Using recycled materials to enhance sustainability in bonded fabrics.

•Hybrid Solutions: Combining coatings and bondings to achieve a balance between breathability, protection, and durability.

Conclusion:Coating vs TPU Bonded

Fabric coating and TPU bonding are indispensable tools in modern textile production, each offering unique advantages tailored to specific needs. While fabric coating is economical and versatile, TPU bonding excels in durability and environmental sustainability. Understanding the differences between these processes helps manufacturers and designers make informed decisions, ensuring the best performance for their applications. As technology advances, these methods will continue to adapt, driving innovation and meeting the demands of ever-evolving industries.

By leveraging the strengths of both techniques, the textile industry can create high-quality, functional fabrics that cater to diverse consumer and industrial needs.